- All Plans

- Yahoo Press Release

- Bloomberg Press Release + Yahoo Finance

- Business Insider Press Release

- Benzinga Press Release

- Digital Journal Press Release

- US Times Now Press Release

- AP News Press Release

- Yahoo Finance Press Release

- Street Insider Press Release

- MSN News Press Release

- USA Today Press Release

ProleanTech Announces Expanded Laser Cutting Services to Enhance Precision and Versatility Across Industries

China, 19th Oct 2024 – ProleanTech, a leader in precision manufacturing and engineering solutions, is proud to announce the expansion of its state-of-the-art laser cutting services. This advancement will allow the company to provide even greater precision, versatility, and efficiency to its clients across a wide range of industries, including automotive, aerospace, electronics, and medical device manufacturing.

The newly enhanced laser cutting services leverage cutting-edge technology to deliver unparalleled accuracy in cutting intricate designs and materials of various thicknesses. With applications ranging from prototyping to mass production, ProleanTech aims to meet the growing demand for high-quality, cost-effective solutions in an increasingly competitive market.

Laser cutting is useful in the fast-paced industrial sector. It makes precise cuts in long-lasting materials like steel and makes it easy to design complex designs. The versatility and accuracy of laser cutting have made it a vital tool in various sectors.

What Is Laser Cutting?

For precise, clean cuts, nothing beats laser cutting. It uses a strong laser beam that can melt, burn, or even vaporize the material. Laser beams can focus up to 15 kilowatt of power onto a few millimeters’ diameter. After being exposed to the laser beam, materials that are appropriate for laser cutting go through vaporization. Many industries, like automotive, aerospace, fashion, and electronics, use this method.

Modern CNC laser cutting machines use this technology and a advanced motion control system to cut styles in a variety of metal sheet.

CNC Laser Cutting

Coordinated CNC Laser Cutting Made Easy. One major boost is computer numerical control (CNC) laser cutting. It integrates CNC with laser technology to automate the cutting process. CNC systems enable the laser to be precisely controlled. It makes it possible to create complex shapes that would be difficult to do by hand. A succession of consistent, high-quality cuts is the end product.

Benefits of Using a Laser Cutter:

Check out these advantages of laser cutting that will make it the obvious choice.

Speed:

It has a fast speed to cut the components in seconds. That’s much faster than plasma or water jet cutting.

Versatility:

Thin metals are best cut using cold cutting techniques such as routing, sawing, and machining. However, when it comes to AR400 and other really strong materials, they really struggle. Laser cutting gives precise precision regardless of material hardness.

Cost:

Laser cutting might lower product prices when compared to more conventional methods. Moreover, it is a cost-effective solution due to a minimal power usage.

Steel Laser Cutting for Precision:

When dealing with long-term materials, the steel laser cutter is an essential tool. Cutting precision as fine as 0.2 mm is possible with modern CNC machinery, such laser cutters. Their techniques of control are quite precise.

Accurate and clean cuts are achieved even with thick sheets when laser cutting applies. It works well with stainless and mild steel. It finds usage in the construction, automotive, and heavy machinery sectors, among many others.

Metal Fixtures with Flexibility:

Using a laser to cut sheet metal is another great use of this cutting technology. Its precision and versatility are unparalleled. In addition to aluminum and stainless steel, it works with many other metals. Making bespoke components is beneficial for organizations since it increases efficiency while lowering waste. This economical technique might be useful for large-scale projects.

Aluminum laser cutting:

Aluminum is commonly laser cut because it is inexpensive and long-lasting. Its strong reflectivity and thermal conductivity make cutting it hard. Aluminum can be precisely sliced using a laser. There is no compromise to the material’s quality. The aerospace and electronics industries are perfect examples of this.

5. Laser-Cut Nylon:

The properties of nylon include strength and flexibility. The plastics and textiles sectors have made it a popular material for laser cutting. The use of a laser allows for clean, precise cuts that leave no visible edges. It works well with many different kinds of materials, including fashion and machinery.

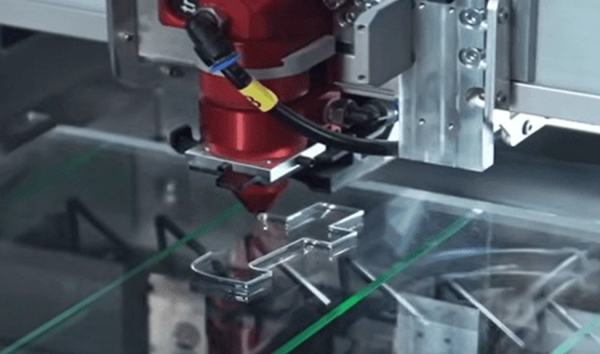

Laser Cutting Machine

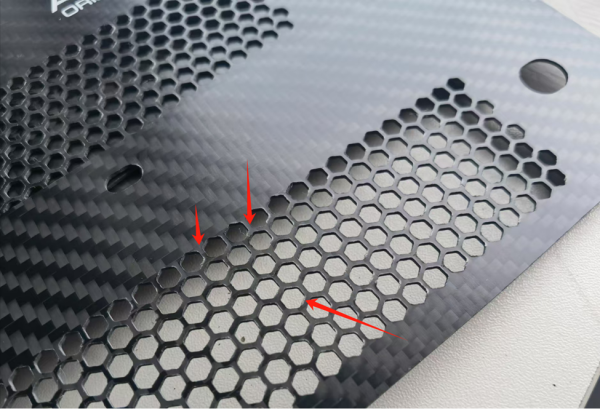

Laser Cutting Defect On Carbon Fiber

In the process of laser cutting, achieving high precision and quality is paramount. However, various factors can lead to defects that compromise the integrity of the cut. Common issues such as thermal damage, burring, and dross formation can affect the final product’s functionality and appearance. Understanding these potential laser cutting defects is crucial for optimizing cutting parameters and selecting appropriate materials. By addressing these defects proactively, manufacturers can enhance production efficiency and product quality

Laser Cutting Types:

For cutting metal, the two most popular laser options are (Co2) and fiber.

1. Fiber Lasers:

Fiber lasers cutters can process a wider range of materials due to recent technology advances. The capacity to cut reflecting materials is one of the advantages of fiber lasers.

These tools are best for polished stainless steels, aluminum, brass, and copper. This is due to the unique way the laser beam reaches the material. A fiber laser can convert about 80% of its input energy into cutting power. This is its biggest advantage for commercial operators. It makes the laser efficient and cost-effective.

2. Co2 Laser Cutting:

This method is older. It involves feeding a current into a chamber of carbon dioxide gas. This excites the particles within the tube. Lenses and mirrors concentrate them to create a powerful beam of light.

With an efficiency of about 20%, CO2 lasers waste a lot of energy as heat and light instead of producing laser light. Co2 lasers can cut the toughest metals at 20 kilowatts. They need only 100 watts or less to cut paper, card, and fabric.

Best laser for metal cutting?

Common metal cutting laser systems include fiber and Co2 lasers. Like any other option, they each have pros and cons.

Many Co2 lasers can’t cut some brass and copper grades. But, fiber lasers can cut a wide range of materials. These lasers, however, are far more costly. Co2 lasers are more energy-intensive than fiber lasers. So, they cost more to operate and maintain.

If you can afford it, a fiber laser is often the best choice for most materials. A 6-axis laser cutter is required for cutting non-flat rolling shapes such as angles, beams, or tubes.

Laser Cutting Costs

The price of laser cutting should be considered while looking into laser cutting services. Factors like as material, thickness, and design complexity might impact the price. Thanks to technological advancements, these services are now more affordable without sacrificing quality. Technological developments in lasers have made the procedure more economical, allowing businesses to get outstanding cuts at reasonable pricing.

Laser Cutting Services:

Picking the right laser cutting service is essential for getting excellent results. ProLean works best for customized business solutions. Whether you need a precise cut in steel, nylon, or aluminum, ProLean is your go-to laser cutting solution. ProLean ensures compliance with strict requirements using innovative laser cutting technology and experienced skills. We offer CNC laser cutting and custom designs with quality, efficiency, and affordability.

Final Thought

Laser cutting is the future of manufacturing. It works with any material, from heavy steel to delicate nylon. With ProLean’s help, your project will get great attention to detail. Contact us now to see how we can use technology and experts to realize your vision!

Media Contact

Organization: Proleantech

Contact Person: Huáng

Website: https://proleantech.com/

Email: Send Email

Country: China

Release Id: 19102418674