Core Components: Excavator Parts in Heavy Equipment Performance

Excavator parts transcend their mechanical nature, serving as the linchpin of heavy equipment performance. Their meticulous maintenance and attentive care are of utmost importance for achieving efficiency

China, 11th Oct 2023: Excavator parts transcend their mechanical nature, serving as the linchpin of heavy equipment performance. Their meticulous maintenance and attentive care are of utmost importance for achieving efficiency, safety, productivity, durability, and environmental stewardship across construction, mining, and various heavy-duty applications.

The performance of each excavator part exerts a direct influence on the overall efficiency, safety, and productivity of the machine. The keys to unlocking their full potential lie in regular maintenance, the timely replacement of worn components, and unwavering adherence to safety protocols. When excavator parts operate in seamless harmony, they empower heavy equipment to execute a diverse spectrum of tasks with precision, encompassing digging, loading, material handling, and meticulous excavation.

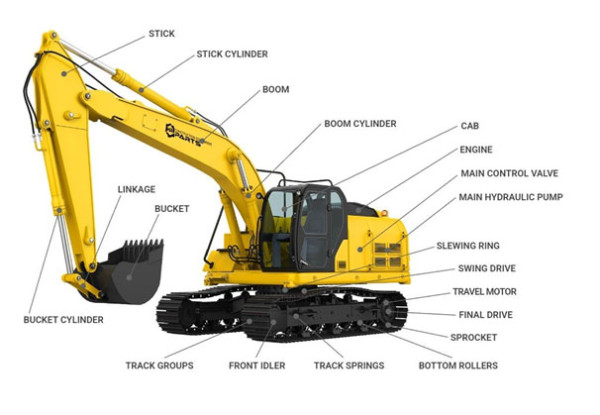

What Are the Key Excavator Components?

- Digger Boom

The digger boom, often simply referred to as the “boom,” stands as a pivotal component within excavators and other heavy equipment employed across construction, mining, and excavation sectors.

- Excavator Root Ripper

An excavator root ripper emerges as a specialized attachment meticulously crafted for the utilization of excavators and hefty machinery. Its designated purpose encompasses applications in construction, forestry, and land-clearing endeavors.

- Heavy-Duty Rock Buckets

Heavy-duty rock buckets materialize as specialized attachments meticulously fashioned to complement robust machinery, including excavators, loaders, and backhoes. These stalwart attachments are indispensable in industries such as construction, mining, quarrying, and various heavy-duty applications.

- Pin Grabber Quick Coupler

The pin grabber quick coupler assumes the role of a specialized attachment tailor-made for heavy machinery, such as excavators and backhoes. Its primary function revolves around streamlining and accelerating the efficient exchange of attachments.

Embracing Eco-Friendly Materials and Designs for a Sustainable Future

- Sustainability Contributions

Excavator parts assume a multifaceted role in advancing sustainability within the heavy equipment industry. By prioritizing their proper maintenance and care, we not only enhance efficiency and productivity but also contribute to resource conservation, waste reduction, and a diminished environmental footprint. This collective effort aligns with a more sustainable and eco-friendly approach to heavy equipment operation.

- Waste Reduction

When excavator parts are well-maintained, they minimize wear and tear, resulting in a notable reduction in material waste. This reduction translates into fewer replacements, less disposal of old parts, and a decreased demand for raw materials.

- Indoor Air Quality

The proficient operation of excavator parts, including the engine and hydraulic system, actively contributes to fuel efficiency. Consequently, this reduces fuel consumption and curtails greenhouse gas emissions, in perfect alignment with our environmental sustainability objectives.

Overall

In a world where sustainability takes center stage, the significance of excavator parts in achieving environmentally friendly and cost-efficient heavy equipment operation cannot be emphasized enough. By giving utmost priority to proper maintenance, timely replacements, and adherence to safety and environmental regulations, industries can unlock the full potential of excavator parts. This ensures efficient and responsible performance even in the face of demanding construction and excavation challenges.

At EDCM, our specialization lies in the production of structural components for construction machinery. We possess the capability to customize these components to precisely match our customers’ requirements. Our cutting-edge facilities feature CNC machining centers, welding robots, and a fully-equipped physical and chemical laboratory, all of which empower us to uphold stringent quality control standards. Additionally, we leverage ERP and PDM systems to respond promptly to market demands, ensuring the utmost efficiency in our operations.

Media Contact

Organization: EDCM

Contact Person: EDCM

Website: https://www.edcmgroup.com/

Email: linado@edcmgroup.com

Country: China

Release Id: 1110236967