Process Solutions International Announces MAX2000 Progressive Cavity Pumps Delivering Unmatched Reliability and Performance

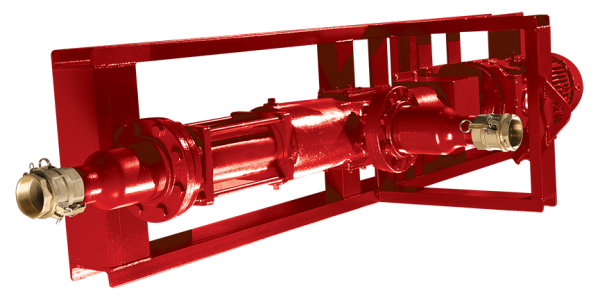

Process Solutions International announces the MAX2000® Progressive Cavity Pumps, offering industry-leading reliability, innovative design, and broad applications across oil & gas, environmental, and industrial markets.

MAX2000® Cavity Pump Launch

Houston, TX – October 15, 2025 – Process Solutions International, a global leader in fluid handling solutions, proudly introduces the MAX2000® Progressive Cavity Pumps. These pumps set new standards for reliability, efficiency, and durability in industrial fluid transfer. With nearly three decades of expertise and ISO 9001 certification, the company continues to serve industries worldwide with precision-engineered products.

Moreover, the MAX2000® pumps combine innovation with practical design. Therefore, they provide accurate fluid rate monitoring for a wide range of applications, including environmental remediation and food service operations. In addition, operators benefit from improved performance and reduced downtime compared to conventional pumps.

Unlike conventional pump systems, the MAX2000® integrates a proprietary double-seal pin joint. As a result, this feature eliminates contamination risks and extends operational life. Consequently, operators experience less downtime and enjoy safe, continuous operation even in demanding industrial environments.

“Dependable pumping solutions are essential for industries where efficiency and uptime directly impact profitability,” said Kye Keliehor of Process Solutions International. “The MAX2000® pumps combine advanced design with top-quality craftsmanship to meet that demand.”

Innovative Engineering And Features

The MAX2000® pumps combine advanced engineering with practical features for versatility and strength. Specifically:

- Proprietary Double-Seal Pin Joint – This industry-exclusive design compresses over an inch, reducing contamination risks.

- Modular Design – Simplifies maintenance and allows operators to adjust pumping elements without maintaining extensive inventory.

- Extended Unit Life – Rugged construction and system-matched replacement parts minimize downtime and support long-term use.

Furthermore, these features ensure operators can maintain efficiency, safety, and reliability even under heavy-duty conditions. In addition, the design helps reduce overall maintenance costs, making it a cost-effective choice for industrial applications.

Flexible Installation And Components

The MAX2000® offers a skid-mounted configuration that eases transport, installation, and setup for various industrial projects. Additionally, 98% of the components are manufactured in the U.S., ensuring high-quality standards.

Moreover, these pumps perform reliably across oil and gas, mining, environmental services, and food processing industries. Therefore, their versatility makes them ideal for companies seeking industrial cavity pumps that can adapt to specialized applications without sacrificing efficiency or safety. As a result, operators can maximize productivity while maintaining operational safety.

Presale Value And Reliability

Operators can explore detailed specifications to understand the MAX2000® design philosophy. Progressive cavity pumps handle viscous fluids, slurries, and sensitive materials with consistent flow and minimal shear. Furthermore, the MAX2000® enhances reliability while reducing maintenance demands, giving operators a competitive edge.

Unlike generic alternatives, these pumps use system-matched components and a modular platform. Thus, operators can adjust them quickly to meet changing project requirements. Consequently, this combination of flexibility and dependability makes the MAX2000® a future-proof investment for any industrial operation.

Global Reach And Support

Operators seeking progressive cavity pumps in Houston or global markets can access Process Solutions International’s regional operations and service support. Moreover, the company emphasizes innovation and customer success. Every MAX2000® pump undergoes rigorous ISO 9001 testing to ensure safety, durability, and high performance.

“Process Solutions International’s reputation is built on delivering equipment that lasts,” Keliehor said. “The MAX2000® embodies this philosophy, combining cutting-edge design with proven dependability.”

Since 1991, Process Solutions International has supplied fluid handling, material handling, gas management, and cleaning & filtration systems across five continents. By consistently focusing on reliability, efficiency, and safety, the company continues to deliver engineered solutions for industries ranging from oilfield drilling to environmental remediation.

Contact Info

Kye Keliehor

Process Solutions International

Phone: +1 (281) 893-4774

Website: https://psimax2000.com/

Company Details

Organization: Process Solutions International

Contact Person: Kye Keliehor

Website: https://psimax2000.com/

Email: Send Email

Contact Number: +12818934774

Address: 7519 Prairie Oak Dr

City: Houston

State: TX

Country: United States

Release Id: 16102535414